The Curve is a spectacular state-of-the-art theatre, based in the heart of Leicester’s vibrant Cultural Quarter that has developed a reputation for producing, programming and touring a bold and diverse programme of musicals, plays, new work, dance and opera.

Looking for new seating for your theatre, cinema, or sports hall? Contact Auditoria today to discuss our bespoke seating solutions to upgrade your venue.

Leicester Theatre Job Requirement and CAD Design

Revitalizing a Venue: Our Latest Project in Theatre Design and Installation

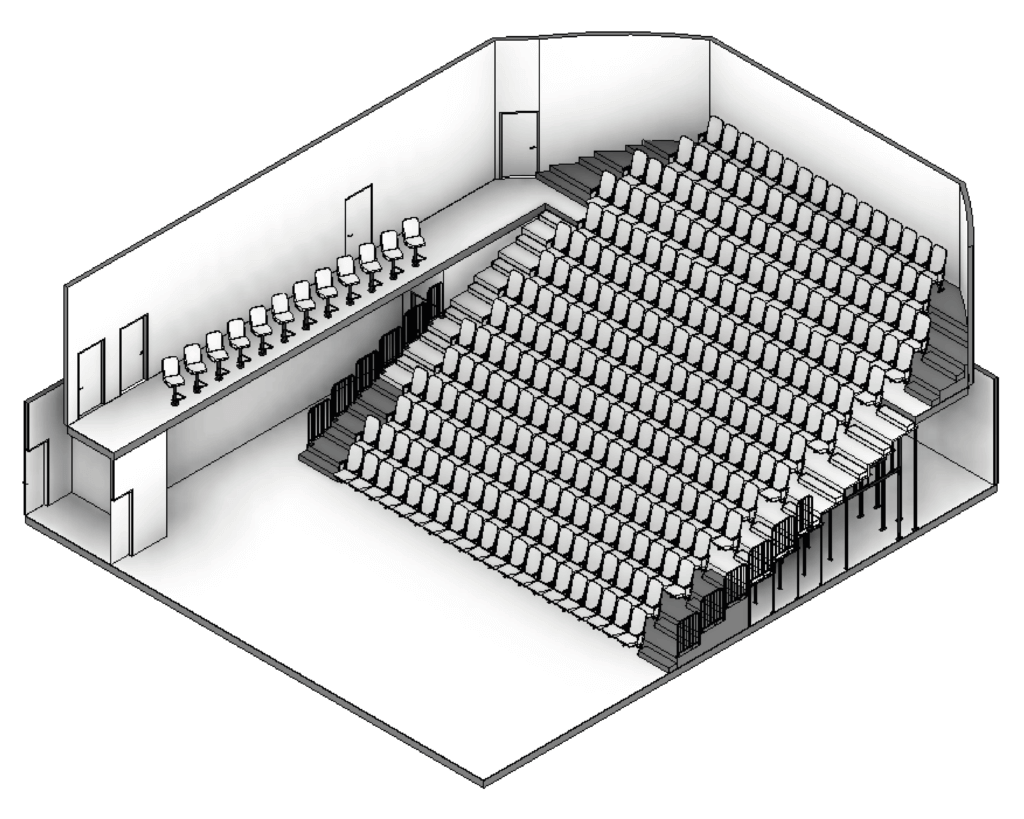

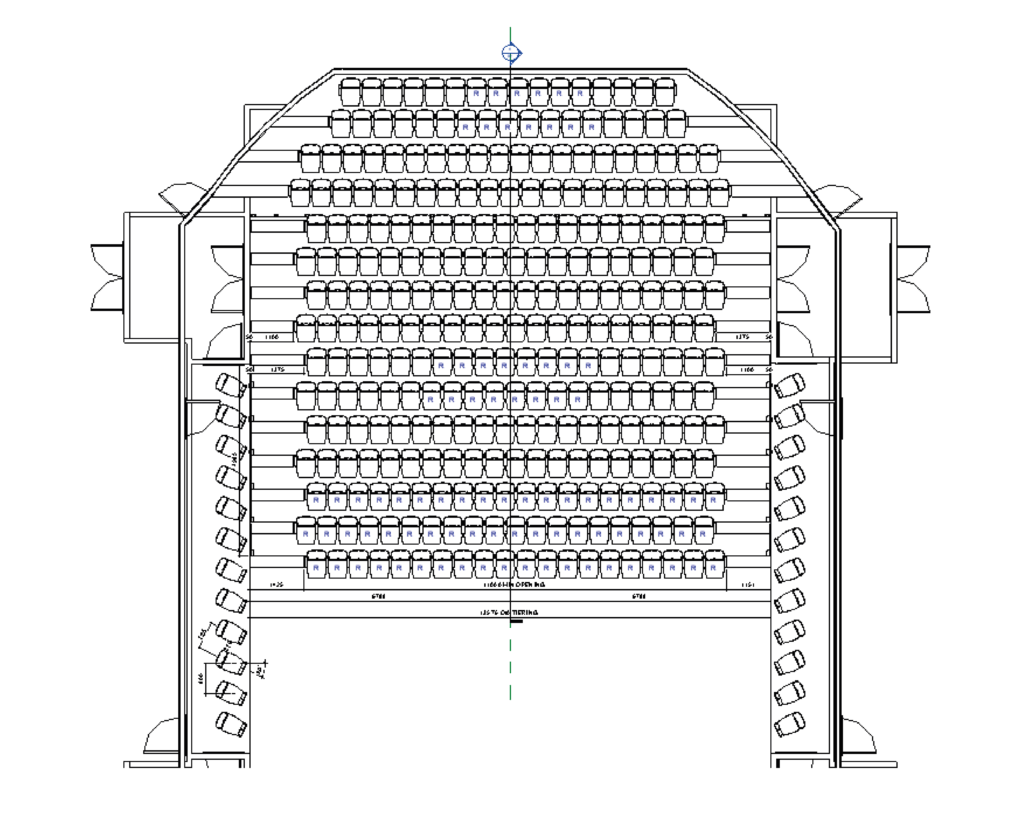

We had the pleasure of breathing new life into the theatre’s studio theatre room by designing and installing the new fixed tiering and seating. Our state-of-the-art TS4 auto tip theatre chairs were used to complete the project. The new design includes 294 chairs spread over 15 tiers of raked carpeted tiering, complete with aisle lighting. Additionally there are 29 removable chairs plus 12 high stools with foot bar on each side of the balcony.

The chairs are covered in luxurious red velvet and the 90mm thick foam seat and 25mm foam back provide unparalleled comfort. The black powder-coated metalwork and stylish beech-stained and lacquered arms give the chairs a modern, sophisticated look.

Designing the Perfect Theatre Space: Our Process

Our team began with a thorough in-person site survey to ensure that the theatre seating was a perfect fit for the space. To attain the highest level of accuracy, we utilized the latest technologies and software to map the space. Detailed visual concepts and designs were created in both 2D and 3D, as well as physical samples for customer review.

Manufacturing Process

In-house Production: the Key to excellence

All our tiering and seating options are made entirely in-house, using locally purchased materials and responsible sourcing methods. We utilize CNC manufacturing for large-scale production to ensure accuracy, consistency, and quality. This hybrid approach guarantees that each piece is of the highest calibre and meets our exacting standards. The stylish arms of our chairs are crafted from solid wood and coated with premium, non-toxic lacquer to increase durability and longevity. This vintage theatre look, combined with modern style, is sure to impress.

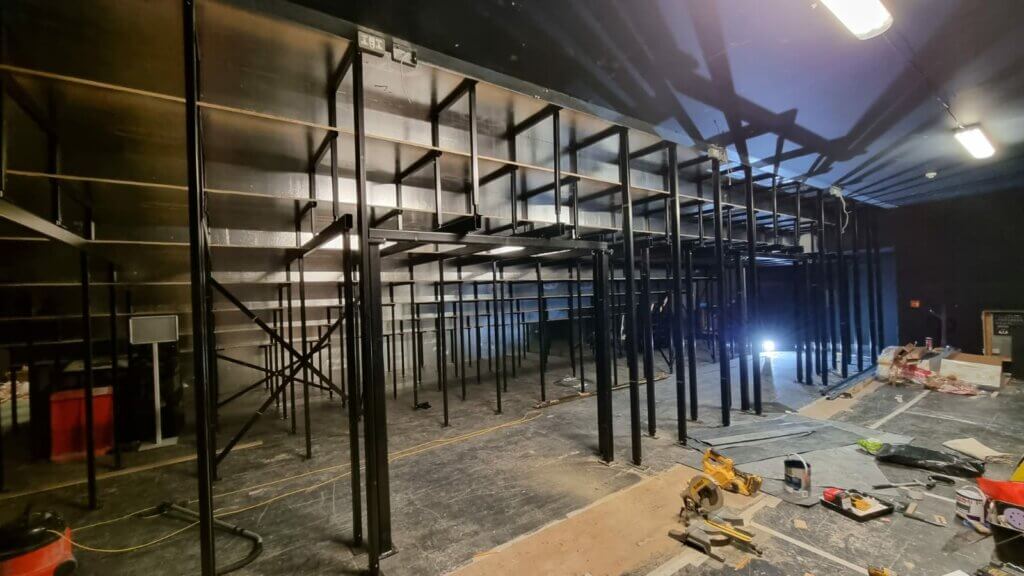

We have invested heavily in steel manufacturing and take pride in producing all aspects of our metal products. We utilise a range of tools and machines including lasers, press breaks, lathes, robots, and traditional welders. Our locally-sourced steel is then finished in our powder-coated department. By manufacturing everything under one roof, we have the ability to thoroughly control the process and guarantee consistently high-quality products.

On Site Installation

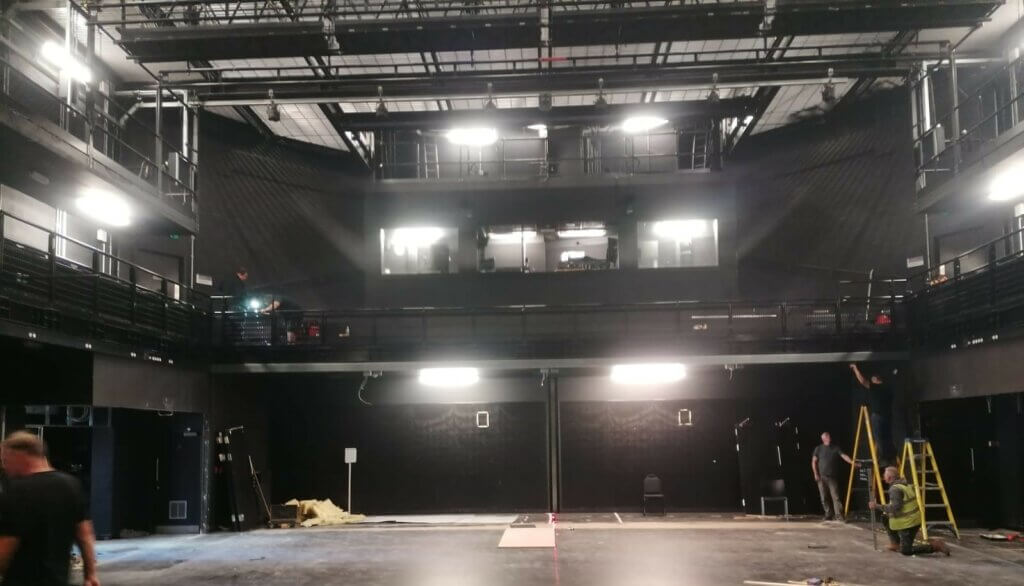

The Final Touches: Completion of the Project

Our comprehensive turnkey approach ensures that every aspect of the project is taken care of – from removing existing seating and structures to preparing the space for its inaugural audience. Our teams of expert engineers are committed to providing top-quality work, handling everything from the strip-out and tiering structure installation to carpeting, aisle lighting, diffuser holes and chair installation with precision and safety.

Discover how Auditoria upgraded the seating for the University of Hertfordshire in this case study.

Comments are closed.